Gleasoniigiya ze-bevel ezijikelezayoluhlobo olukhethekileyo lwegiya ye-bevel eyenzelwe ukuhambisa amandla phakathi kweeshafti ezidibanayo, ngokuqhelekileyo kwi-engile ye-90 degrees. Okwenza inkqubo yeGleason yahluke yindlela yayo eyahlukileyo yokwenza amazinyo kunye nendlela yokwenza, ebonelela ngentshukumo egudileyo, amandla aphezulu e-torque, kunye nokusebenza okuzolileyo. Ezi giya zisetyenziswa kakhulu kwiitransmissions zeemoto, zoshishino, kunye neenqwelo-moya apho ukuthembeka nokuchaneka kubalulekile.

Inkqubo yeGleason yaphuhliswa ukuze iphucule indlela echanekileyo nefanelekileyo yokusebenza.iigiya ze-bevel zerolngokungenisa izinyo eligobileyo nelimile okwesipili. Olu hlobo lwesipili luvumela ukudibana kancinci kancinci phakathi kwamazinyo, kunciphisa kakhulu ingxolo kunye nokungcangcazela ngelixa kuvumela isantya esiphezulu sokujikeleza kunye nomthamo womthwalo. Uyilo lukwaphucula umlinganiselo woqhagamshelwano kunye namandla omphezulu, ukuqinisekisa ukudluliselwa kwamandla ngokufanelekileyo phantsi kwemithwalo enzima okanye enamandla.

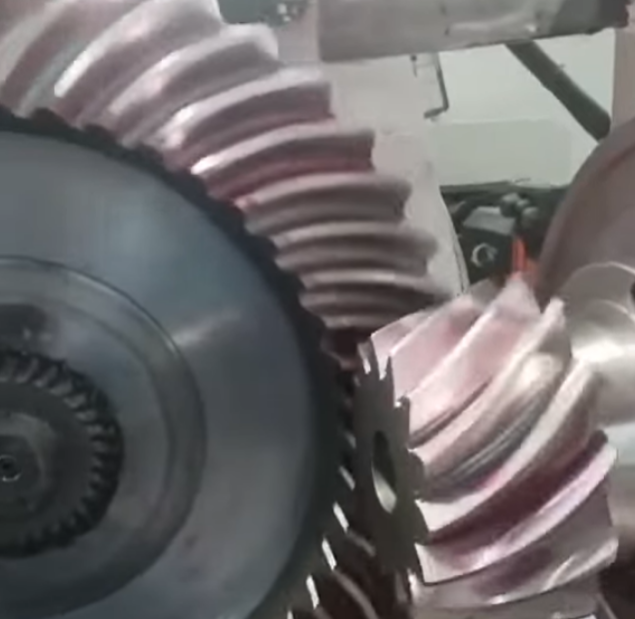

Isibini ngasinye segiya ye-Gleason spiral bevel siqulathe i-pinion kunye negiya yokudibana, eveliswe nge-geometry ehambelanayo. Inkqubo yokuvelisa ikhethekile kakhulu. Iqala ngokubumba okanye ukuphosa ngokuchanekileyo ii-blanks zentsimbi ye-alloy, ezifana ne-18CrNiMo7-6, kulandele ukusika okurhabaxa, ukuhombisa, okanye ukubumba ukwenza uhlobo lwegiya lokuqala. Iindlela eziphambili ezifana noomatshini be-5-axis, ukuskiya, kunye nokusika okuqinileyo ziqinisekisa ukuchaneka okuphezulu kunye nokugqitywa komphezulu okwenziwe kakuhle. Emva konyango lobushushu olufana ne-carburization (58–60 HRC), iigiya ziyalaphiswa okanye zigaywa ukuze kufezekiswe i-meshing epheleleyo phakathi kwe-pinion kunye negiya.

Ijiyometri yeegiya ze-Gleason spiral bevel ichazwa ziiparameters ezininzi ezibalulekileyo—i-angle ejikelezayo, i-angle yoxinzelelo, umgama wekhoni yepitch, kunye nobubanzi bobuso. Ezi parameters zibalwe ngokuchanekileyo ukuqinisekisa iipateni zoqhagamshelwano lwamazinyo ezichanekileyo kunye nokusasazwa komthwalo. Ngexesha lokuhlolwa kokugqibela, izixhobo ezinje ngomatshini wokulinganisa (CMM) kunye nohlalutyo loqhagamshelwano lwamazinyo (TCA) ziqinisekisa ukuba iseti yegiya iyahlangabezana neklasi yokuchaneka kwe-DIN 6 okanye ye-ISO 1328-1 efunekayo.

Isebenza, iGleason spiraliigiya zebhevelzibonelela ngokusebenza kakuhle okuphezulu kunye nokusebenza okuzinzileyo naphantsi kweemeko ezinzima. Amazinyo agobileyo abonelela ngokudibana okuqhubekayo, kunciphisa uxinzeleleko kunye nokuguguleka. Oku kuwenza afaneleke kwiimoto ezahlukeneyo, iibhokisi zegiya zelori, oomatshini abanzima, iinkqubo zokuqhuba zaselwandle, kunye nezixhobo zamandla. Ukongeza, ukukwazi ukwenza ngokwezifiso ijometri yamazinyo kunye nomgama wokufaka kuvumela iinjineli ukuba zilungiselele uyilo lwe-torque ethile, isantya, kunye nemida yendawo.

I-Gleason-type spiral bevel gear — itafile yokubala ebalulekileyo

| Into | Ifomula / Ukubonakaliswa | Iinguqu/Amanqaku |

|---|---|---|

| Iiparamitha zokufaka | (z_1,\ z_2,\ m_n,\ \alpha_n,\ \Sigma,\ b,\ T) | amazinyo e-pinion/gear (z); imodyuli eqhelekileyo (m_n); i-engile yoxinzelelo oluqhelekileyo (\alpha_n); i-engile yeshaft (\Sigma); ububanzi bobuso (b); i-torque edluliselweyo (T). |

| Ububanzi besalathiso (ubuphakathi) | (d_i = z_i , m_n) | i = 1 (pinion), 2 (gear). Ububanzi obuphakathi/besalathiso kwicandelo eliqhelekileyo. |

| Ii-angles zepitch (cone) | (\delta_1,\ \delta_2) kangangokuba (\delta_1+\delta_2=\Sigma) kunye (\dfrac{\sin\delta_1}{d_1}=\dfrac{\sin\delta_2}{d_2}) | Sombulula ii-engile zekhowuni ezihambelana nomlinganiselo wamazinyo kunye ne-engile ye-shaft. |

| Umgama wekhowuni (umgama wepitch apex) | (R = \dfrac{d_1}{2\sin\delta_1} = \dfrac{d_2}{2\sin\delta_2}) | Umgama ukusuka kwincopho yekhowuni ukuya kwisangqa sepitshi ulinganiswa ngokwe-generatrix. |

| Iphimbo elijikelezayo (eliqhelekileyo) | (p_n = \pi m_n) | Ipitshi ethe tye kwicandelo eliqhelekileyo. |

| Imodyuli enqamlezileyo (malunga) | (m_t = \dfrac{m_n}{\cos\beta_n}) | (\beta_n) = i-engile eqhelekileyo ejikelezayo; itshintsha phakathi kwamacandelo aqhelekileyo nanqamlezayo njengoko kufuneka. |

| I-engile ejikelezayo (ulwalamano oluphakathi/olunqamlezileyo) | (\tan\beta_t =\tan\beta_n\cos\delta_m) | (\delta_m) = i-angle ephakathi kwekhowuni; sebenzisa ii-transforms phakathi kwee-angles eziqhelekileyo, ezinqamlezileyo, kunye neziphakathi ezijikelezayo. |

| Ingcebiso yobubanzi bobuso | (b = k_b , m_n) | (k_b) idla ngokukhethwa ukusuka kwi-8 ukuya kwi-20 kuxhomekeke kubungakanani kunye nokusetyenziswa; jongana noyilo lwendlela ukuze ufumane ixabiso elichanekileyo. |

| Isihlomelo (umyinge) | (a \malunga ne-m_n) | Isixa-mali esiqhelekileyo sobunzulu obupheleleyo; sebenzisa iitafile zomlinganiselo wamazinyo ochanekileyo ukuze ufumane amaxabiso achanekileyo. |

| Ububanzi obungaphandle (incam) | (d_{o,i} = d_i + 2a) | i = 1,2 |

| Ububanzi beengcambu | (d_{f,i} = d_i – 2h_f) | (h_f) = i-dedendum (ukusuka kwiimilinganiselo zenkqubo yegiya). |

| Ubukhulu bamazinyo ajikelezayo (malunga) | (s \malunga \dfrac{\pi m_n}{2}) | Kwijometri ye-bevel sebenzisa ubukhulu obulungisiweyo obuvela kwiitafile zamazinyo ukuze ufumane ukuchaneka. |

| Amandla e-tangential kwisangqa se-pitch | (F_t = \dfrac{2T}{d_p}) | (T) = i-torque; (d_p) = ububanzi bepitch (sebenzisa iiyunithi ezihambelanayo). |

| Uxinzelelo lokugoba (olwenziwe lula) | (\sigma_b = \dfrac{F_t \cdot K_O \cdot K_V}{b \cdot m_n \cdot Y}) | (K_O) = into egqithisileyo, (K_V) = into eguquguqukayo, (Y) = into ebumbayo (ijiyometri egobileyo). Sebenzisa i-AGMA/ISO epheleleyo egobileyo kuyilo. |

| Uxinzelelo loqhagamshelwano (uhlobo lweHertz, olulula) | (\sigma_H = C_H \sqrt{\dfrac{F_t}{d_p , b} \cdot \dfrac{1}{\frac{1-\nu_1^2}{E_1}+\frac{1-\nu_2^2}{E_2}}}) | (C_H) i-geometry constant, (E_i,\nu_i) i-elastic moduli yezinto kunye ne-Poisson ratios. Sebenzisa ii-equations ezipheleleyo zoqhagamshelwano-uxinzelelo ukuqinisekisa. |

| Umlinganiselo woqhagamshelwano (ngokubanzi) | (\varepsilon = \dfrac{\text{arc of action}}{\text{base pitch}}) | Kwiigiya ze-bevel, bala usebenzisa i-pitch cone geometry kunye ne-spiral angle; ngokuqhelekileyo kuvavanywa ngeetafile okanye isoftware yoyilo lwegiya. |

| Inani lamazinyo elibonakalayo | (z_v \malunga \dfrac{d}{m_t}) | Iluncedo ekujongeni unxibelelwano/ukunciphisa umlinganiselo; (m_t) = imodyuli enqamlezileyo. |

| Ukuhlolwa kwamazinyo amancinci / ukunqunyulwa okuncinci | Sebenzisa ubuncinci bemeko yamazinyo ngokusekelwe kwi-angle ejikelezayo, i-angle yoxinzelelo kunye nobungakanani bamazinyo | Ukuba u-(z) ungaphantsi komlinganiselo ofunekayo, kufuneka izixhobo ezingaphantsi okanye ezikhethekileyo. |

| Useto lomatshini/lokusika (inyathelo loyilo) | Misela ii-engile zentloko yomsiki, ukujikeleza kwe-cradle kunye nokubeka i-indexing kwi-geometry yenkqubo yegiya | Ezi setingi zithathwe kwijiyometri yegiya kunye nenkqubo yokusika; landela inkqubo yomatshini/yezixhobo. |

Itekhnoloji yemveliso yanamhlanje, efana noomatshini bokusika nokugaya izixhobo ze-CNC bevel, iqinisekisa umgangatho ohambelanayo kunye nokutshintshiselana. Ngokudibanisa uyilo oluncediswa yikhompyutha (CAD) kunye nokulinganisa, abavelisi banokwenza ubunjineli obubuyela umva kunye novavanyo olubonakalayo ngaphambi kwemveliso yokwenyani. Oku kunciphisa ixesha kunye neendleko ngelixa kuphucula ukuchaneka kunye nokuthembeka.

Ngamafutshane, ii-Gleason spiral bevel gears zimele indibaniselwano egqibeleleyo ye-geometry ephucukileyo, amandla ezinto, kunye nokuchaneka kokwenziwa. Ukukwazi kwazo ukuhambisa umbane ogudileyo, osebenzayo, nohlala ixesha elide kuzenze zaba yinxalenye ebalulekileyo kwiinkqubo zanamhlanje zokuqhuba. Nokuba zisetyenziswa kwicandelo leemoto, lemizi-mveliso, okanye leenqwelo-moya, ezi gear ziyaqhubeka nokuchaza ukugqwesa kwintshukumo kunye nokusebenza koomatshini.

Ixesha leposi: Oktobha-24-2025