Ukuqonda i-Helix Angle of Gears: Inkcazo Ukubaluleka kunye nezicelo

Kwi-gear engineering, enye yezona parameter zibalulekileyo ezichaphazela ukusebenza, ukusebenza kakuhle, kunye nenqanaba lengxolo yi-helix angle. Le ngcamango ibaluleke kakhulu kwiiigiya zehelical, ezisetyenziswa kakhulu kwiitransmission zeemoto, kwiibhokisi zegiya zoshishino, kwi-aerospace, kwiirobhothi, nakwiimashini ezinzima. Ukuqonda ukuba yintoni i-engile ye-helix, indlela eyichaphazela ngayo indlela esebenza ngayo kwiigiya, kunye nesizathu sokuba ibalulekile kubalulekile kwiinjineli kunye nabavelisi abajonge ukuphucula uyilo lweegiya.

Yintoni iHelix Angle?

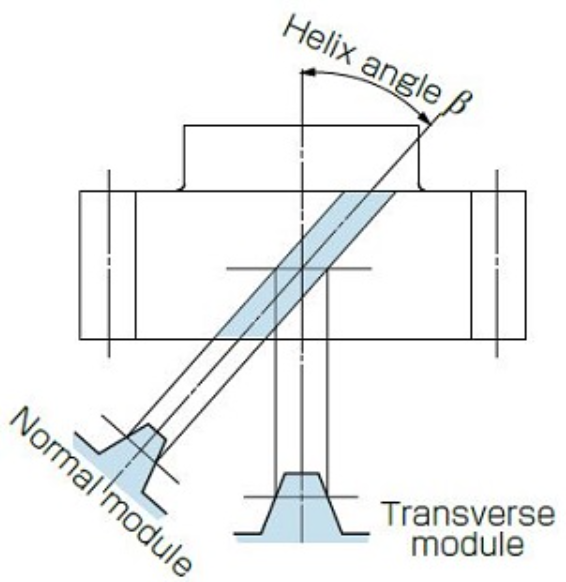

I-engile ye-helix ibhekisa kwi-engile eyenziwe phakathi kwezinyo legiya kunye ne-axis yokujikeleza kwegiya. Kwiigiya ezijikelezayo, amazinyo awanqunyulwa ngqo ebusweni begiya, njengakwiigiya ezijikelezayo, kodwa abekwe kwi-engile, okwenza imilo ye-helix ijikeleze umjikelo wegiya. Le engile inokwahluka ukusuka kwiidigri ezincinci ukuya kuthi ga kwi-45°, kuxhomekeke kwisicelo kunye neemfuno zokusebenza.

-

Ii-engile ezincinci ze-helix(umz., i-15°) ibangela ukusebenza okubushelelezi xa kuthelekiswa neegiya ze-spur kodwa isaqhubeka nokwenza izinto ngokulula.

-

Ii-engile ezinkulu ze-helix(umz., 30° nangaphezulu) zibonelela ngokubandakanyeka okuthambileyo ngakumbi kunye nomthamo ophezulu wokuthwala umthwalo kodwa zivelisa i-axial thrust enkulu, ekufuneka ilawulwe ngeebheringi okanye ii-thrust washers.

Ukubaluleka kwe-Helix Angle kuYilo lweeGear

I-engile ye-helix idlala indima ephambili ekumiseleni iimpawu zokusebenza kweegiya ze-helical:

-

Ukuhanjiswa kwamandla okuthambileyo

Ngenxa yamazinyo ajijekileyo, ukubandakanyeka kwegiya kuhamba kancinci kancinci kunokuba kube ngoko nangoko. Oku kunciphisa imithwalo yokukhwankqiswa, ukungcangcazela, kunye nengxolo, okwenza iigiya ezijikelezayo zilungele ukusetyenziswa ngesantya esiphezulu kunye namandla aphezulu. -

Ukusasazwa koMthwalo

I-engile enkulu ye-helix inyusa umlinganiselo woqhagamshelwano, oko kuthetha ukuba amazinyo amaninzi abandakanyeka ngaxeshanye. Oku kusasaza umthwalo phezu kwamazinyo amaninzi, kuphucula ukuqina kunye nomthamo womthwalo. -

Uxinzelelo lwe-Axial

Ingxaki ye-engile ye-helix kukuba ingenisa amandla e-axial kwi-shaft yegiya. Okukhona i-engile ye-helix inkulu, kokukhona umthwalo we-axial uphezulu, nto leyo efuna ukulungiswa okuqinileyo kweebheringi. -

Ukusebenza kakuhle vs. Amandla Ukurhweba

Nangona ii-engile eziphezulu ze-helix zinyusa amandla kunye nokuthamba, zinokunciphisa ukusebenza kakuhle kancinci ngenxa yokwanda kokungqubana okutyibilikayo. Abayili kufuneka balinganisele ezi zinto ngokusekelwe kwisicelo esicetywayo.

Usetyenziso lwee-Angles zeHelix ezahlukeneyo

Ukukhethwa kwe-engile ye-helix kuxhomekeke kuhlobo loomatshini kunye neemfuno zokusebenza:

-

Uthumelo lweeMoto

Iigiya ze-helical ezinee-engile ze-helix ezijikeleze i-20–30° zixhaphakile kwiibhokisi zegiya zeemoto kuba zibonelela ngokusebenza okuzolileyo, okugudileyo kunye nokudluliselwa kwe-torque ephezulu. -

Iibhokisi zeegiya zemizi-mveliso

Ii-engile ezinkulu ze-helix zihlala zisetyenziselwa ukwandisa umthamo wokuthwala umthwalo kwiimashini ezinzima ezifana nee-conveyors, ii-crushers, kunye nee-cement mills. -

Izixhobo zeRobhothi kunye neNgcaciso

Ii-engile ezincinci ze-helix okanye uyilo lweegiya ze-helical ezinqamlezileyo zikhethwa kwiibhokisi zegiya ezincinci nezikhaphukhaphu ezifuna ulawulo oluchanekileyo lokuhamba. -

Izicelo zeenqwelo-moya

Ii-engile ze-helix ezilungeleleneyo zibalulekile ekunciphiseni ingxolo, ukungcangcazela, kunye nokuguguleka kwiibhokisi zegiya ze-turbine ezikhawulezayo.

I-Helix Angle vs. I-Angle yoXinzelelo

Kubalulekile ukuba ungabhidanisii-engile ye-helixnei-engile yoxinzeleloI-engile yoxinzelelo inxulumene nolwalathiso lwamandla phakathi kwamazinyo ane-meshing, ngelixa i-engile ye-helix ibhekisa ngokukodwa kwindlela amazinyo ajonge ngayo i-engile. Zombini iiparameter kufuneka ziqwalaselwe kunye ukuze kuyilo olufanelekileyo lwegiya.

Ixesha lokuthumela: Agasti-21-2025