Kukho iintlobo ezininzi zeegiya, kuquka iigiya ezisilinda ezithe tye, iigiya ezisilinda ezijikelezayo, iigiya ze-bevel, kunye neegiya ze-hypoid esizazisayo namhlanje.

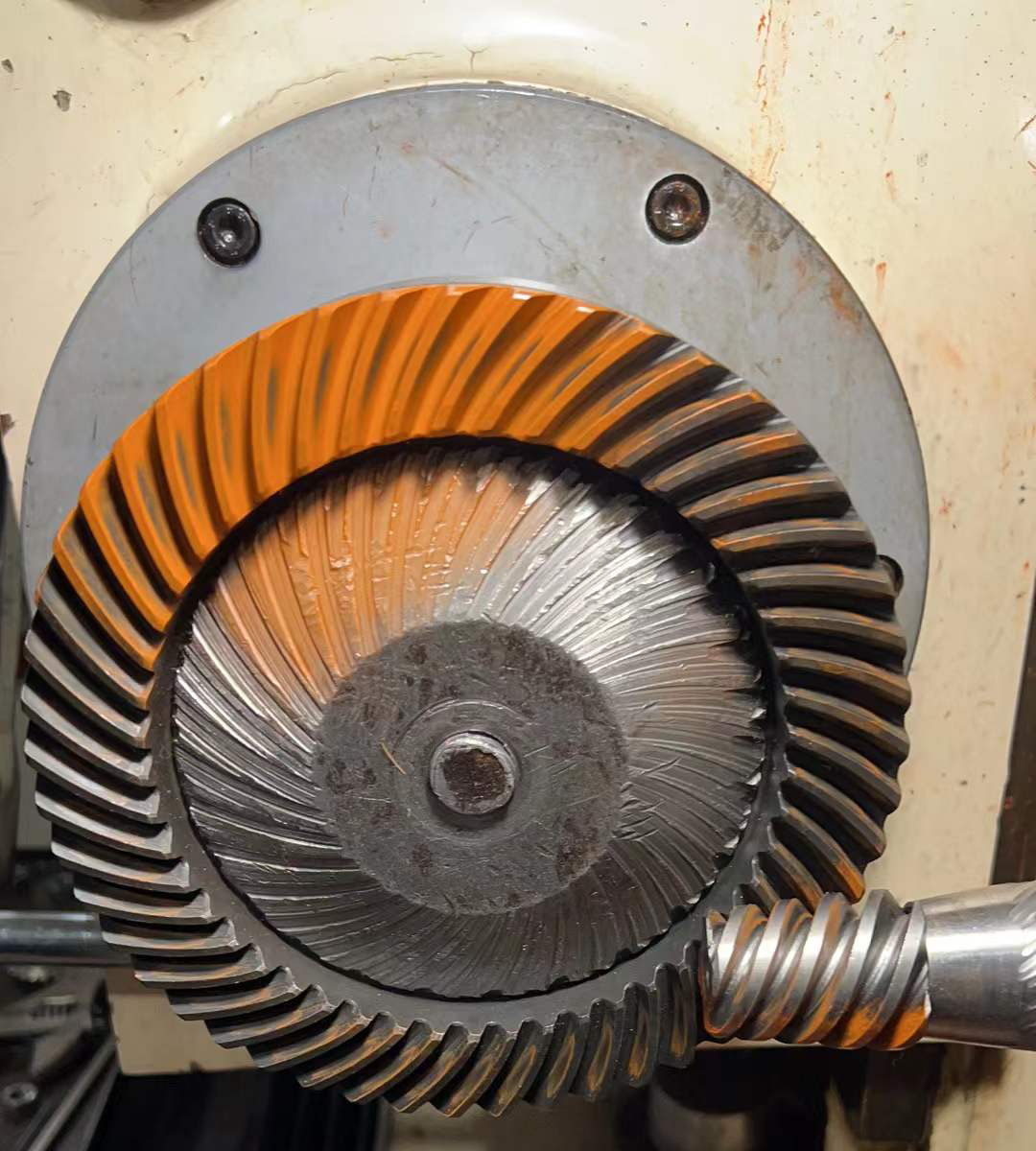

1) Iimpawu zeegiya ze-hypoid

Okokuqala, i-engile ye-shaft yegiya ye-hypoid yi-90°, kwaye ulwalathiso lwe-torque lungatshintshwa lube yi-90°. Olu lukwaluguquko lwe-engile olufunekayo rhoqo kwishishini lamandla eemoto, eenqwelo moya, okanye omoya. Kwangaxeshanye, iigiya ezimbini ezinobukhulu obahlukeneyo kunye namanani ahlukeneyo amazinyo zidityaniswa ukuze kuvavanywe umsebenzi wokwandisa i-torque kunye nesantya esinciphileyo, esibizwa ngokuba "yi-torque ekhulisayo nenciphisa isantya". Ukuba umhlobo oqhube imoto, ingakumbi xa eqhuba imoto yesandla xa efunda ukuqhuba, xa enyuka intaba, umqeqeshi uya kukuvumela ukuba uye kwigiya ephantsi, eneneni, kukukhetha iigiya ezimbini ezinesantya esikhulu, esibonelelwa ngesantya esiphantsi. I-torque engaphezulu, ngaloo ndlela inika amandla angakumbi kwisithuthi.

Zithini iimpawu zeegiya ze-hypoid?

Utshintsho kwi-engile ye-torque yokudlulisela

Njengoko kukhankanyiwe ngasentla, utshintsho lwe-angular lwamandla e-torque lunokwenzeka.

Uyakwazi ukumelana nemithwalo emikhulu

Kwishishini lamandla omoya, ishishini leemoto, nokuba ziimoto zabakhweli, iiSUV, okanye izithuthi zorhwebo ezifana neelori zokuthutha, iilori, iibhasi, njl.njl., ziya kusebenzisa olu hlobo ukubonelela ngamandla amakhulu.

Uthumelo oluzinzileyo ngakumbi, ingxolo ephantsi

Ii-engile zoxinzelelo zamacala asekhohlo nasekunene amazinyo ayo zinokungangqinelani, kwaye icala elityibilikayo le-gear meshing likwicala lobubanzi bamazinyo kunye necala leprofayili yamazinyo, kwaye indawo engcono ye-gear meshing inokufumaneka ngoyilo kunye netekhnoloji, ukuze lonke udluliselo lube phantsi komthwalo. Elilandelayo lisengcono kakhulu ekusebenzeni kwe-NVH.

Umgama ohlengahlengiswayo we-offset

Ngenxa yoyilo olwahlukileyo lomgama ongemva, ingasetyenziselwa ukuhlangabezana neemfuno ezahlukeneyo zoyilo lwesithuba. Umzekelo, kwimeko yemoto, ingahlangabezana neemfuno zokususwa komhlaba wesithuthi kwaye iphucule amandla okudlula kwemoto.

2) Iindlela ezimbini zokucubungula izixhobo ze-hypoid

Igiya enamacala amabini yaziswa yiGleason Work ngo-1925 kwaye iye yaphuhliswa iminyaka emininzi. Okwangoku, kukho izixhobo ezininzi zasekhaya ezinokucutshungulwa, kodwa ukucutshungulwa okuchanekileyo nokuphezulu kwenziwa kakhulu zizixhobo zangaphandle iGleason kunye ne-Oerlikon. Ngokuphathelele ukugqitywa, kukho iinkqubo ezimbini eziphambili zokusila iigiya kunye neenkqubo zokusila, kodwa iimfuno zenkqubo yokusila iigiya zahlukile. Kwinkqubo yokusila iigiya, inkqubo yokusila iigiya icetyiswa ukuba kusetyenziswe ukusila ubuso, kwaye inkqubo yokusila icetyiswa ukuba kusetyenziswe ukusila ubuso.

Iigiya ezicutshungulwa luhlobo lokusila ubuso zimazinyo anciphileyo, kwaye iigiya ezicutshungulwa luhlobo lokusila ubuso zimazinyo alinganayo nokuphakama, oko kukuthi, ukuphakama kwamazinyo kubuso obukhulu nobuncinci kuyafana.

Inkqubo eqhelekileyo yokucubungula imalunga nokufudumeza ngaphambi kwexesha, emva konyango lobushushu, ize igqitywe. Kwisitovu sobuso, kufuneka sicolwe kwaye silinganiswe emva kokufudumeza. Ngokubanzi, iigiya ezimbini zicolwe kunye kufuneka zilinganiswe xa zidityaniswa kamva. Nangona kunjalo, ngokwethiyori, iigiya ezineteknoloji yokugaya iigiya zingasetyenziswa ngaphandle kokuzifanisa. Nangona kunjalo, ekusebenzeni kwangempela, xa kujongwa impembelelo yeempazamo zokuhlanganisa kunye nokuguqulwa kwenkqubo, imo yokufanisa isasetyenziswa.

3) Uyilo nophuhliso lwe-triple hypoid luyinkimbinkimbi ngakumbi, ingakumbi kwiimeko zokusebenza okanye iimveliso eziphezulu ezineemfuno eziphezulu, ezifuna amandla, ingxolo, ukusebenza kakuhle kothumelo, ubunzima kunye nobukhulu begiya. Ke ngoko, kwinqanaba loyilo, kudla ngokufuneka udibanise izinto ezininzi ukuze kufunyanwe ibhalansi ngokuphindaphinda. Kwinkqubo yophuhliso, kudla ngokufuneka ulungise ushicilelo lwamazinyo ngaphakathi koluhlu lotshintsho oluvumelekileyo lwendibano ukuqinisekisa ukuba inqanaba lokusebenza elifanelekileyo lisenokufikelelwa phantsi kweemeko zokwenyani ngenxa yokuqokelelwa kwetyathanga lobukhulu, ukuguquguquka kwenkqubo kunye nezinye izinto.

Ixesha lokuthumela: Meyi-12-2022