Iinkqubo zegiya zidlala indima ebalulekileyo kwizixhobo ezahlukeneyo zoomatshini, ziqinisekisa ukuhanjiswa kwamandla okuhamba kakuhle nangokufanelekileyo. Nangona kunjalo, ukusebenza kweenkqubo zegiya kuxhomekeke kakhulu ekuchanekenii-gear meshingNokuba kukho ukuphambuka okuncinci kunokukhokelela ekungasebenzi kakuhle, ukuguguleka okukhulu, kwanokungaphumeleli okukhulu. Kweli nqaku, siza kujonga izinto ezichaphazela ukuchaneka kwe-gear mesh kwaye sihlolisise ukubaluleka kwazo ekuqinisekiseni ukusebenza kakuhle kwenkqubo yegiya.

Iprofayili yezinyo leGiya:

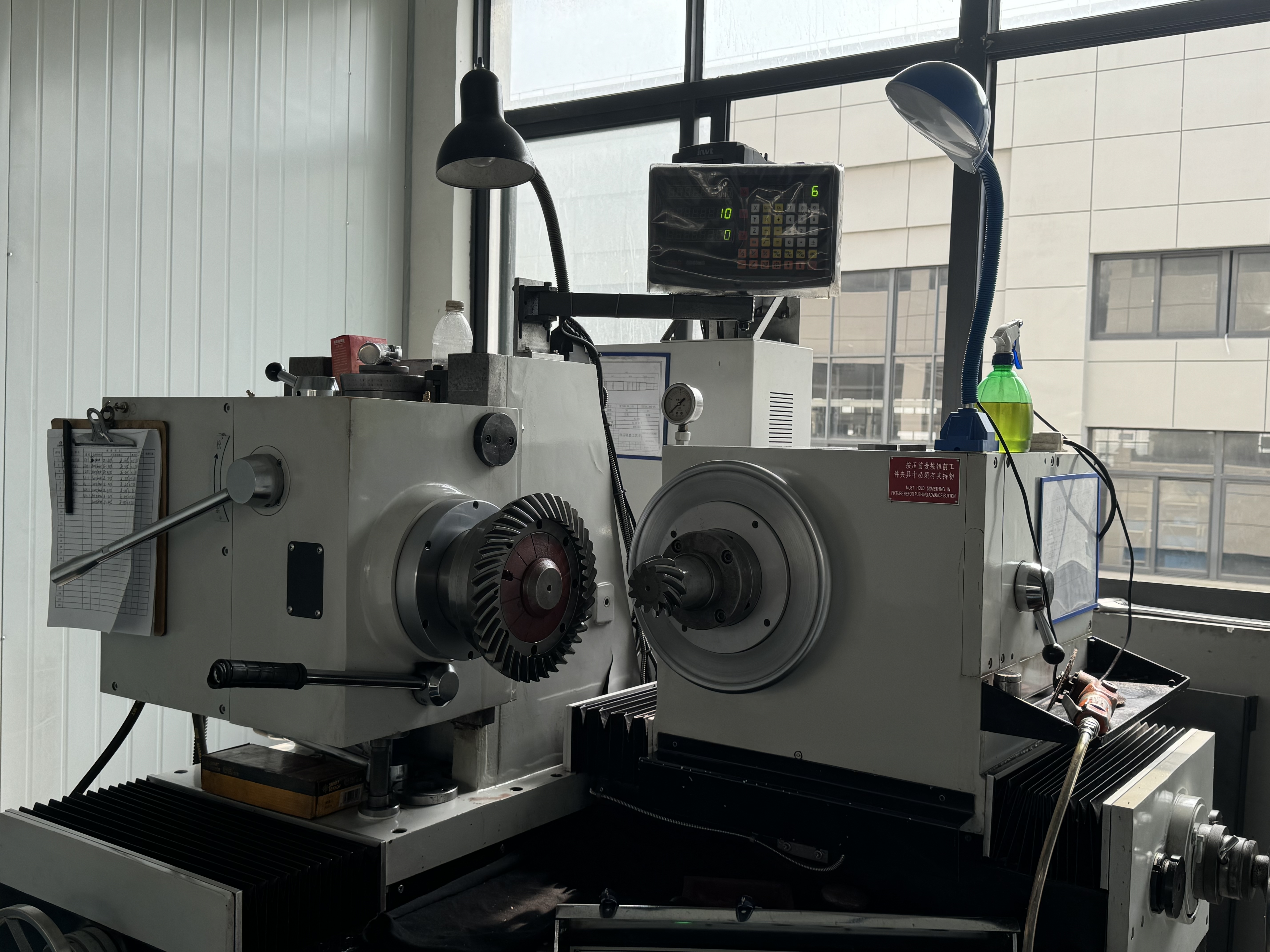

Iprofayili yamazinyo egiya mhlawumbi yeyona nto iphambili echaphazela ukuchaneka kwe-gear mesh. Amazinyo kufuneka akhiwe ngokuchanekileyo ukuqinisekisa ukubandakanyeka okufanelekileyo kunye nokunciphisa umva. Nakuphi na ukuphambuka kwiprofayili yamazinyo efanelekileyo kunokukhokelela ekuthwaleni okungalinganiyo, ukwanda kwengxolo, kunye nokusebenza okunciphileyo. Iindlela zokuvelisa zanamhlanje ezifana noomatshini be-CNC ziye zaphucula kakhulu amandla okuvelisa iiprofayili zamazinyo egiya ezichanekileyo.

Ukunyamezelana Kwemveliso:

Iinkqubo zokuvelisa ngokungenakuphepheka zizisa ukunyamezelana, okunokuchaphazela ukuchaneka kwe-gear mesh. Utshintsho kubungakanani, ukugqitywa komphezulu, kunye neempawu zezinto ezibonakalayo kunokuchaphazela indlela ii-gear ezisebenzisana ngayo ngexesha lokufaka i-mesh. Ukunyamezelana okuqinileyo kunye namanyathelo okulawula umgangatho ngexesha lokuvelisa kubalulekile ukuqinisekisa ukusebenza kwe-gear rhoqo.

Ulungelelwaniso kunye nokuhlanganiswa:

Ukulungelelaniswa okufanelekileyo kunye nokuhlanganiswa kweizixhoboiinkqubo zibalulekile ekufezekiseni ukuchaneka kwe-mesh efanelekileyo. Ukulungelelaniswa kakuhle kwee-shafts, isithuba esingafanelekanga phakathi kweegiya, okanye ukulayisha kwangaphambili kweebheringi ngendlela engafanelekanga kunokukhokelela ekuthwaleni okungalinganiyo kunye nokuguguleka kwangethuba. Ingqwalasela enzulu kwiinkqubo zokuhlanganisa, kubandakanya ukusetyenziswa kwezixhobo zokulungelelanisa kunye neenkcukacha ze-torque, iyimfuneko ukunciphisa le micimbi.

Ukuthambisa:

Ukuthambisa okusebenzayo kubalulekile ekunciphiseni ukungqubana kunye nokuguguleka phakathi kwamazinyo egiya. Ukuthambisa okunganelanga okanye okungafanelekanga kunokubangela ukungqubana okwandileyo, ubushushu obugqithisileyo, kunye nokuguguleka okukhawulezileyo. Ukukhethwa kwegrisi efanelekileyo, kunye nokugcinwa rhoqo kunye nokubeka esweni amanqanaba okuthambisa, kubalulekile ekugcineni ukuchaneka kwegrisi ngokuhamba kwexesha.

Iimeko Zokusebenza:

Indawo yokusebenza ingachaphazela ukuchaneka kwe-gear mesh. Izinto ezinje ngokuguquguquka kobushushu, imithwalo yokutsha, kunye nongcoliseko zinokuchaphazela ukusebenza kwe-gear.izixhoboiinkqubo ezinezokhuseleko ezifanelekileyo kunye nokuqwalasela iimeko zokusebenza ezicetywayo kunokunceda ukunciphisa ezi ziphumo nokuqinisekisa ukusebenza okuthembekileyo.

Ukuguguleka kunye nokuwohloka:

Ekuhambeni kwexesha, iigiya zinokuba nokuguguleka nokuwohloka, nto leyo echaphazela ukuchaneka kweemesh zazo. Amasuntswana arhabaxayo, ukuthambisa okunganelanga, okanye imithwalo egqithisileyo inokukhawulezisa ukuguguleka kwaye ikhokelele kutshintsho kwijiyometri yeegiya. Ukuhlolwa rhoqo kunye nokugcinwa kubalulekile ekufumaneni nasekulungiseni iingxaki zokuguguleka ngaphambi kokuba zibe yingozi ekusebenzeni kweegiya.

Ukufezekisa nokugcinaizixhoboUkuchaneka kwe-mesh kubalulekile ekuqinisekiseni ukusebenza okuthembekileyo nokusebenzayo kweenkqubo zoomatshini. Ngokuqonda izinto ezichaphazela ukuchaneka kwe-mesh yegiya kunye nokusebenzisa amanyathelo afanelekileyo ngexesha loyilo, ukwenziwa, ukuhlanganiswa, kunye nokusebenza, iinjineli zinokuphucula ukusebenza kwegiya kwaye zandise ubomi beenkqubo zegiya. Ukuqhubela phambili okuqhubekayo kubuchwepheshe bokuvelisa kunye nezixhobo, kunye neendlela zokulawula umgangatho ezingqongqo, kuya kuqhubeka nokuphucula ukuchaneka kwe-mesh yegiya kunye nokuqhuba ubuchule kubunjineli boomatshini.

Ixesha leposi: Meyi-07-2024