Iindawo ezininzi zeizixhobo ezintsha zokunciphisa amandlakwayeizixhobo zeemotoLe projekthi ifuna ukudutyulwa emva kokugaywa kwezixhobo, nto leyo eya konakalisa umgangatho womphezulu wezinyo, kwaye ichaphazele nokusebenza kwe-NVH kwenkqubo. Eli phepha lifunda uburhabaxa bomphezulu wezinyo kwiimeko ezahlukeneyo zenkqubo yokudutyulwa kunye neendawo ezahlukeneyo ngaphambi nasemva kokudutyulwa. Iziphumo zibonisa ukuba ukudutyulwa kuya kwandisa uburhabaxa bomphezulu wezinyo, obuchaphazeleka ziimpawu zamacandelo, iiparameter zenkqubo yokudutyulwa kunye nezinye izinto; Phantsi kweemeko zenkqubo yokuvelisa ibhetshi ekhoyo, uburhabaxa obukhulu bomphezulu wezinyo emva kokudutyulwa buphindwe ka-3.1 kunangaphambi kokudutyulwa. Impembelelo yoburhabaxa bomphezulu wezinyo ekusebenzeni kwe-NVH iyaxoxwa, kwaye kucetyiswa amanyathelo okuphucula uburhabaxa emva kokudutyulwa.

Phantsi kwemvelaphi engasentla, eli phepha lixoxa ngezi nkalo zintathu zilandelayo:

Impembelelo yeempawu zenkqubo yokuphuma kwenaliti ekurhabaxekeni komphezulu wamazinyo;

Inqanaba lokukhulisa ukuchama kwenaliti phezu koburhabaxa bomphezulu wamazinyo phantsi kweemeko zenkqubo yokuvelisa ibhetshi ekhoyo;

Impembelelo yokwanda kokurhabaxa komphezulu wamazinyo ekusebenzeni kwe-NVH kunye neendlela zokuphucula ukurhabaxa emva kokuchama ngomjovo.

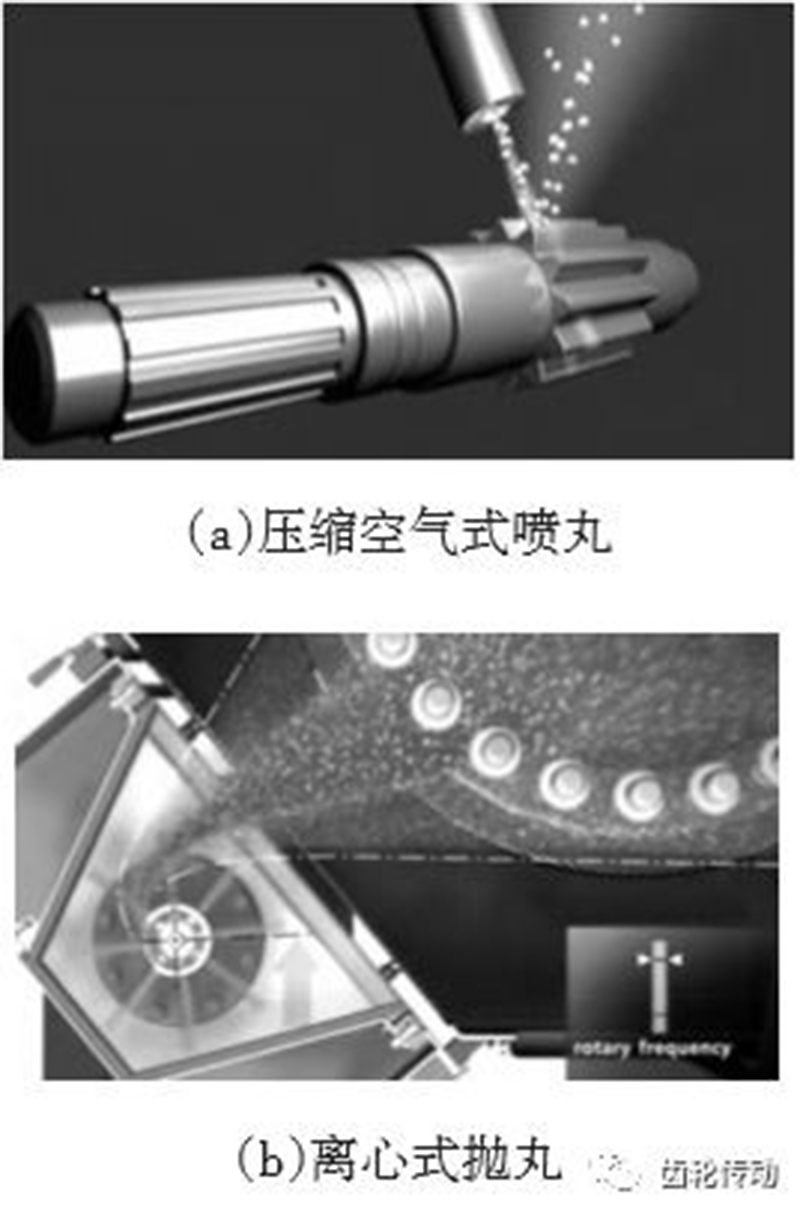

Ukudutyulwa kweembumbulu kubhekisa kwinkqubo apho iimbumbulu ezininzi ezincinci ezinobunzima obuphezulu kunye nokuhamba ngesantya esiphezulu zibetha umphezulu weendawo. Phantsi kwempembelelo yesantya esiphezulu sembumbulu, umphezulu wenxalenye uya kuvelisa imingxuma kwaye kuya kwenzeka ukuguquka kweplastiki. Imibutho ejikeleze iimbumbulu iya kuxhathisa oku kuguquka kwaye ivelise uxinzelelo oluhlala luxinezelekile. Ukugqubana kweendawo ezininzi kuya kwenza umaleko woxinzelelo oluhlala luxinezelekile kumphezulu wenxalenye, ngaloo ndlela kuphucula amandla okudinwa kwenxalenye. Ngokwendlela yokufumana isantya esiphezulu ngembumbulu, ukudutyulwa kweembumbulu ngokubanzi kwahlulwe ngokudutyulwa komoya okucinezelweyo kunye nokudutyulwa kwe-centrifugal, njengoko kubonisiwe kuMfanekiso 1.

Ukuchama komoya ocinezelweyo kuthatha umoya ocinezelweyo njengamandla okutshiza isibhamu esivela kwisibhamu; Ukuchama kompu we-centrifugal kusebenzisa injini ukuqhuba i-impeller ukuba ijikeleze ngesantya esiphezulu ukuze iphose isibhamu. Iiparameter eziphambili zenkqubo yokuchama kompu ziquka amandla okugcwala, ukugubungela kunye neempawu eziphakathi zokuchama kompu (izinto, ubungakanani, imilo, ubulukhuni). Amandla okugcwala yiparameter yokubonakalisa amandla okuchama kompu, ebonakaliswa bubude be-arc (oko kukuthi, inqanaba lokugoba kwesixhobo sovavanyo lwe-Almen emva kokuchama kompu); Izinga lokugubungela libhekisa kumlinganiselo wendawo egutyungelwe ngumngxuma emva kokuchama kompu ukuya kwindawo iyonke yendawo echamayo; Izixhobo zokuchama zompu ezisetyenziswa rhoqo ziquka i-steel wire cutting shot, i-cast steel shot, i-ceramic shot, njl. Ubungakanani, imo kunye nobunzima be-shot peening media zikumgangatho owahlukeneyo. Iimfuneko zenkqubo ngokubanzi zeendawo ze-transmission gear shaft ziboniswe kwiTheyibhile 1.

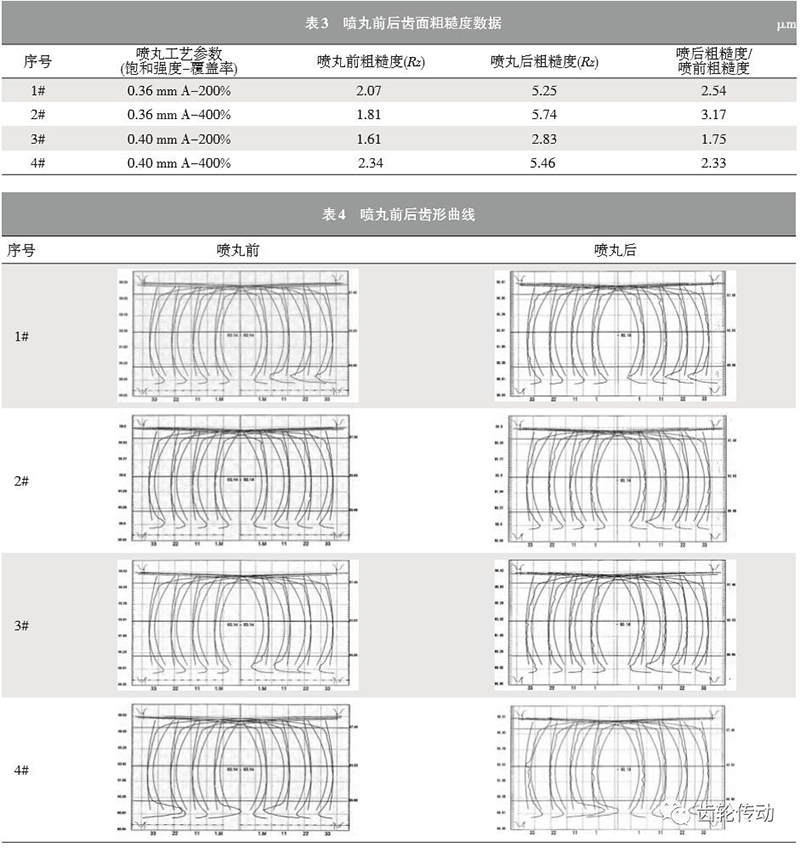

Icandelo lovavanyo yi-intermediate shaft gear 1/6 yeprojekthi ye-hybrid. Ulwakhiwo lwegiya luboniswe kuMfanekiso 2. Emva kokugaywa, isakhiwo esincinci somphezulu wamazinyo sikwiBanga lesi-2, ubunzima bomphezulu yi-710HV30, kwaye ubunzulu bomaleko wokuqina obusebenzayo yi-0.65mm, konke oku kuxhomekeke kwiimfuno zobugcisa. Uburhabaxa bomphezulu wamazinyo ngaphambi kokugaywa kwesibhamu buboniswe kwiTheyibhile 3, kwaye ukuchaneka kweprofayili yamazinyo kuboniswe kwiTheyibhile 4. Kuyabonakala ukuba uburhabaxa bomphezulu wamazinyo ngaphambi kokugaywa kwesibhamu bulungile, kwaye igophe leprofayili yamazinyo ligudileyo.

Isicwangciso sovavanyo kunye neeparamitha zovavanyo

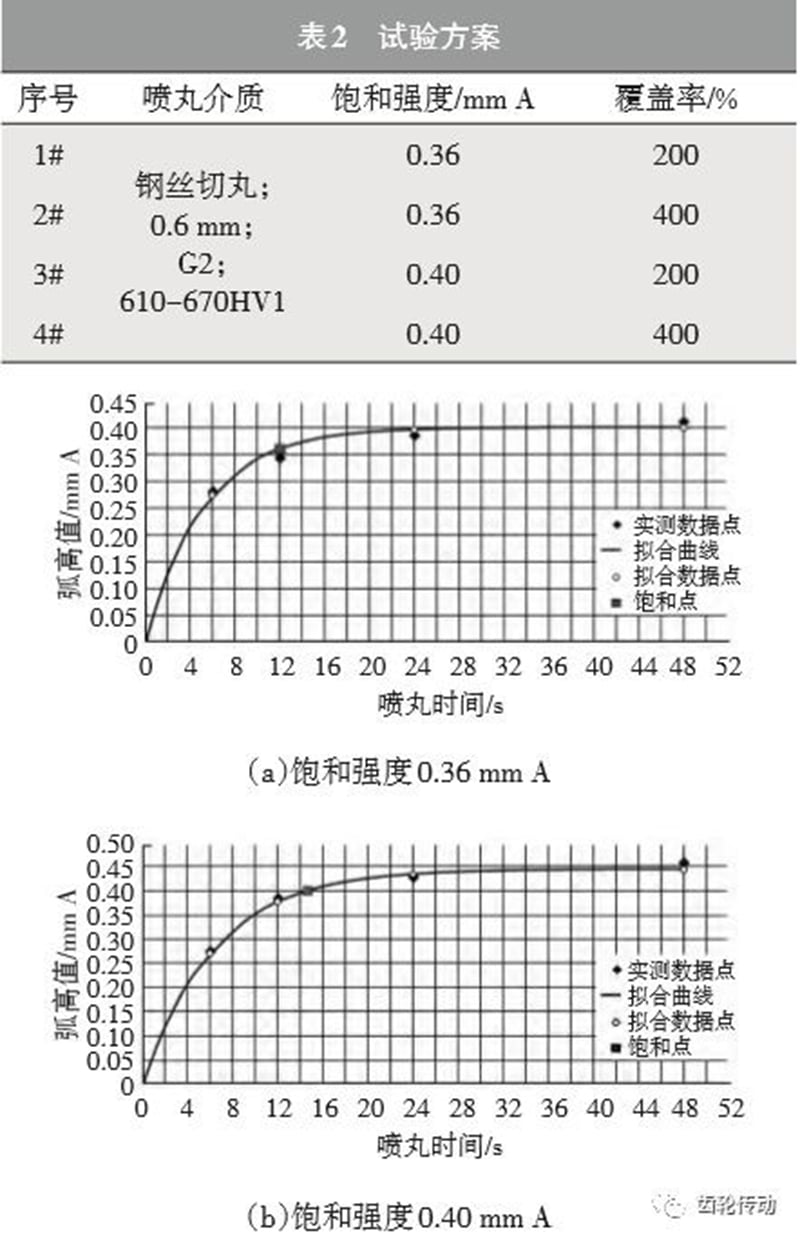

Umatshini wokuvulela i-air shot ocinezelweyo uyasetyenziswa kuvavanyo. Ngenxa yeemeko zovavanyo, akunakwenzeka ukuqinisekisa impembelelo yeempawu ze-shot peeping medium (izinto, ubungakanani, ubulukhuni). Ke ngoko, iimpawu ze-shot peeing medium zihlala zinjalo kuvavanyo. Kuphela yimpembelelo yamandla okugcwala kunye nokugquma koburhabaxa bomphezulu wamazinyo emva kokuvulela i-shot. Jonga iTheyibhile 2 kwiskimu sovavanyo. Inkqubo ethile yokumisela iiparameter zovavanyo yile ilandelayo: zoba i-saturation curve (Umfanekiso 3) ngovavanyo lwe-Almen coupon ukuze ufumane indawo yokugcwala, ukuze uvale uxinzelelo lomoya olucinezelweyo, ukuhamba kwe-steel shot, isantya sokuhamba kwe-nozzle, umgama we-nozzle ukusuka kwiindawo kunye nezinye iiparameter zezixhobo.

iziphumo zovavanyo

Idatha yoburhabaxa bomphezulu wezinyo emva kokuchama ngokudubula iboniswe kwiTheyibhile 3, kwaye ukuchaneka kweprofayili yezinyo kuboniswe kwiTheyibhile 4. Kuyabonakala ukuba phantsi kweemeko ezine zokuchama ngokudubula, uburhabaxa bomphezulu wezinyo buyanda kwaye igophe leprofayili yezinyo liba yingqukuva kwaye lijijeke emva kokuchama ngokudubula. Umlinganiselo woburhabaxa emva kokuchama ngokudubula ngaphambi kokuchama usetyenziselwa ukuchaza ubukhulu boburhabaxa (Itheyibhile 3). Kuyabonakala ukuba ubukhulu boburhabaxa bahlukile phantsi kweemeko ezine zenkqubo.

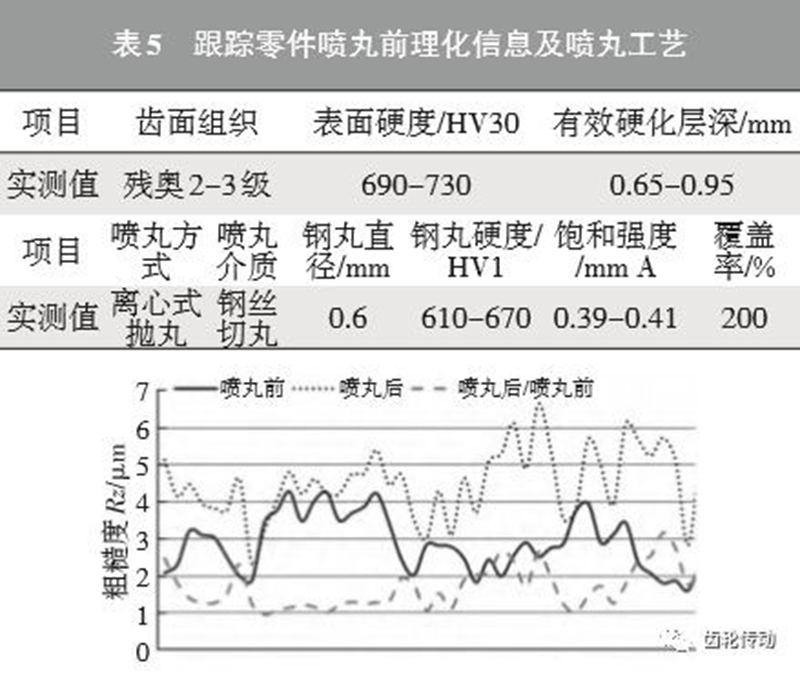

Ukulandelela iBatch of Magnification of Tooth Surface Gradeness by Shot Peening

Iziphumo zovavanyo kwiCandelo lesi-3 zibonisa ukuba uburhabaxa bomphezulu wamazinyo buyanda ngamanqanaba ahlukeneyo emva kokudutyulwa ngeenkqubo ezahlukeneyo. Ukuze kuqondwe ngokupheleleyo ukwandiswa kokudutyulwa koburhabaxa bomphezulu wamazinyo nokunyusa inani leesampuli, kukhethwe izinto ezi-5, iintlobo ezi-5 kunye namacandelo angama-44 xa zizonke ukuze kulandelwe uburhabaxa ngaphambi nasemva kokudutyulwa phantsi kweemeko zenkqubo yokuvelisa ibhetshi yokudutyulwa. Jonga iTheyibhile 5 ngolwazi oluphathekayo nolwekhemikhali kunye nolwazi lwenkqubo yokudutyulwa kweenxalenye ezilandelelweyo emva kokugaywa kwegiya. Uburhabaxa kunye nedatha yokukhulisa umphezulu wamazinyo angaphambili nangasemva ngaphambi kokudutyulwa iboniswe kwiFig. 4. Umfanekiso 4 ubonisa ukuba uluhlu loburhabaxa bomphezulu wamazinyo ngaphambi kokudutyulwa yi-Rz1.6 μ m-Rz4.3 μ m; Emva kokudutyulwa, uburhabaxa buyanda, kwaye uluhlu lokusasazwa yi-Rz2.3 μ m-Rz6.7 μ m; Uburhabaxa obukhulu bunokwandiswa ukuya kumaxesha angama-3.1 ngaphambi kokudutyulwa.

Izinto ezibangela ukuba umphezulu wezinyo ube rhabaxa emva kokudutyulwa

Kuyabonakala kumgaqo wokudubula ngomngxuma ukuba ubunzima obuphezulu kunye nokudubula okuhamba ngesantya esiphezulu kushiya imingxuma engenakubalwa kumphezulu wenxalenye, ongumthombo woxinzelelo olushiyekileyo loxinzelelo. Kwangaxeshanye, le mingxuma inyanzelekile ukuba yonyuse uburhabaxa bomphezulu. Iimpawu zamalungu ngaphambi kokudubula ngomngxuma kunye neeparameter zenkqubo yokudubula ngomngxuma ziya kuchaphazela uburhabaxa emva kokudubula ngomngxuma, njengoko kudweliswe kwiTheyibhile 6. KwiCandelo 3 leli phepha, phantsi kweemeko ezine zenkqubo, uburhabaxa bomphezulu wamazinyo emva kokudubula ngomngxuma buyanda ukuya kumanqanaba ahlukeneyo. Kolu vavanyo, kukho izinto ezimbini eziguquguqukayo, ezizezi, uburhabaxa bangaphambi kokudubula kunye neeparameter zenkqubo (amandla okugcwala okanye ukugubungela), ezingenakuchonga ngokuchanekileyo ubudlelwane phakathi koburhabaxa bokudubula ngomngxuma kunye nento nganye echaphazelayo. Okwangoku, iingcali ezininzi zenze uphando ngale nto, kwaye zabeka imodeli yokuqikelela yethiyori yoburhabaxa bomphezulu emva kokudubula ngomngxuma ngokusekelwe kwi-finite element simulation, esetyenziselwa ukuqikelela amaxabiso oburhabaxa ahambelanayo eenkqubo ezahlukeneyo zokudubula ngomngxuma.

Ngokusekelwe kumava okwenyani kunye nophando lwabanye abaphengululi, iindlela zempembelelo zezinto ezahlukeneyo zinokuqikelelwa njengoko kubonisiwe kwiTheyibhile 6. Kuyabonakala ukuba uburhabaxa emva kokudutyulwa buchaphazeleka ngokupheleleyo zizinto ezininzi, ezikwazezona zinto ziphambili ezichaphazela uxinzelelo olushiyekileyo lokuxinzelela. Ukuze kuncitshiswe uburhabaxa emva kokudutyulwa ngesiseko sokuqinisekisa uxinzelelo olushiyekileyo lokuxinzelela, kufuneka inani elikhulu leemvavanyo zenkqubo ukuze kuqhutyekwe kuphuculwa indibaniselwano yeparameter.

Impembelelo yoburhabaxa bomphezulu wamazinyo ekusebenzeni kwe-NVH kwenkqubo

Iindawo zegiya zikwinkqubo yokudlulisa amandla, kwaye uburhabaxa bomphezulu wamazinyo buya kuchaphazela ukusebenza kwawo kwe-NVH. Iziphumo zovavanyo zibonisa ukuba phantsi komthwalo kunye nesantya esifanayo, kokukhona uburhabaxa bomphezulu bukhula, kokukhona ukungcangcazela kunye nengxolo yenkqubo ikhula; Xa umthwalo kunye nesantya zisanda, ukungcangcazela kunye nengxolo kuyanda ngokucacileyo.

Kwiminyaka yakutshanje, iiprojekthi zezixhobo zokunciphisa amandla ezintsha zinyuke ngokukhawuleza, kwaye zibonisa indlela yophuhliso lwesantya esiphezulu kunye ne-torque enkulu. Okwangoku, i-torque ephezulu yesixhobo sethu esitsha sokunciphisa amandla yi-354N · m, kwaye isantya esiphezulu yi-16000r/min, esiya kwandiswa siye ngaphezulu kwe-20000r/min kwixesha elizayo. Phantsi kweemeko zokusebenza ezinjalo, impembelelo yokwanda koburhabaxa bomphezulu wamazinyo ekusebenzeni kwe-NVH kwenkqubo kufuneka iqwalaselwe.

Amanyathelo okuphucula uburhabaxa bomphezulu wamazinyo emva kokufumana inaliti

Inkqubo yokuchama emva kokugaywa kwegiya inokuphucula amandla okudinwa okuchukumisayo komphezulu wezinyo legiya kunye namandla okudinwa okugoba kwingcambu yezinyo. Ukuba le nkqubo kufuneka isetyenziswe ngenxa yezizathu zamandla kwinkqubo yoyilo lwegiya, ukuze kuqwalaselwe ukusebenza kwe-NVH kwenkqubo, uburhabaxa bomphezulu wezinyo legiya emva kokuchama kwegiya bunokuphuculwa kwezi nkalo zilandelayo:

a. Lungiselela iiparameter zenkqubo yokuchama kwenaliti, kwaye ulawule ukwandiswa koburhabaxa bomphezulu wamazinyo emva kokuchama kwenaliti ngesiseko sokuqinisekisa uxinzelelo olushiyekileyo lokucinezela. Oku kufuna uvavanyo oluninzi lwenkqubo, kwaye ukuguquguquka kwenkqubo akunamandla.

b. Inkqubo yokucofa i-shot edibeneyo iyasetyenziswa, oko kukuthi, emva kokuba i-shot peeping enamandla aqhelekileyo igqityiwe, kongezwa enye i-shot peeping. Amandla enkqubo yokucofa i-shot andayo adla ngokuba mancinci. Uhlobo kunye nobukhulu bezinto ezisetyenziswa ekucofeni zinokulungiswa, njenge-ceramic shot, i-glass shot okanye i-steel wire cut shot enobukhulu obuncinci.

c. Emva kokuchama ngomjovo, kongezwa iinkqubo ezinje ngokupholisha umphezulu wamazinyo kunye nokulolonga ngokukhululekileyo.

Kule phepha, kufundwa ngoburhabaxa bomphezulu wamazinyo kwiimeko ezahlukeneyo zenkqubo yokuchama kwenaliti kunye neendawo ezahlukeneyo ngaphambi nasemva kokuchama kwenaliti, kwaye izigqibo ezilandelayo zithathwe ngokusekelwe kuncwadi:

◆ Ukuchama ngemipu kuya kwandisa uburhabaxa bomphezulu wamazinyo, obuchaphazeleka ziimpawu zamalungu ngaphambi kokuchama ngemipu, iiparameter zenkqubo yokuchama ngemipu kunye nezinye izinto, kwaye ezi zinto zikwayizona zinto ziphambili ezichaphazela uxinzelelo olushiyekileyo lokucinezelwa;

◆ Phantsi kweemeko zenkqubo yokuvelisa ibhetshi ekhoyo, uburhabaxa obukhulu bomphezulu wamazinyo emva kokuchama ngokudubula buphindwe ka-3.1 kunangaphambi kokuchama ngokudubula;

◆ Ukwanda koburhabaxa bomphezulu wamazinyo kuya kwandisa ukungcangcazela kunye nengxolo yenkqubo. Okukhona i-torque kunye nesantya zikhula, kokukhona ukwanda kokungcangcazela kunye nengxolo kucaca ngakumbi;

◆ Uburhabaxa bomphezulu wezinyo emva kokudutyulwa bunokuphuculwa ngokuphucula iiparameter zenkqubo yokudutyulwa, ukudutyulwa kwe-composite shot, ukongeza ukupholisha okanye ukuhombisa ngokukhululekileyo emva kokudutyulwa, njl. Ukulungiswa kweeparameter zenkqubo yokudutyulwa kulindeleke ukuba kulawule ukwanda koburhabaxa ukuya kuthi ga kwi-1.5 amaxesha.

Ixesha lokuthumela: Novemba-04-2022