Ukufumana izinto ezifanelekileyo zokusebenzisa izixhobo

Xa kuyilwa kwaye kusenziwa izixhobo, izinto ezisetyenziswayo ziya kuxhomekeka kuhlobo lwezixhobo ezenziwayo kunye nendlela eziza kusetyenziswa ngayo kunye nendawo eziza kusetyenziswa kuyo.

Kukho iintlobo ezininzi zezinto ezisetyenziswa rhoqo kwizakhiwo zezixhobo, kwaye isixhobo ngasinye sineempawu zaso ezilungileyo zoomatshini kwaye lolona khetho lubalaseleyo.Iindidi eziphambili zezinto ezisetyenzisiweyo zii-alloys zekopolo, ii-alloys zesinyithi, ii-alloys ze-aluminium kunye ne-thermoplastics.

1. Iingxube zekopolo

⚙️Xaukuyila izixhoboukuba iza kuhlaselwa yindawo enokutsha okanye kufuneka ingabi namandla emagnethi, i-alloy yobhedu idla ngokuba lolona khetho lulungileyo.

⚙️Ezona ntlobo zithathu ze-alloy zekopolo zisetyenziswa kakhulu kwiigiya yi-bronze, i-phosphor bronze, kunye ne-aluminium bronze.

⚙️Iigiya ezidla ngokwenziwa nge-alloy yobheduizixhobo zokushukumisakunye neerakhi kwaye ziya kusetyenziswa kwiindawo ezinomthwalo omncinci.

⚙️I-phosphorus bronze iphucula ukuxhathisa ukuguguleka kunye nokuqina kwe-alloy. Ukugqwala okuphezulu kunye nokumelana nokuguguleka kwenza ii-phosphor bronze alloys zibe lukhetho oluhle kakhulu kwiindawo ezine-friction drive ephezulu. Umzekelo:izixhobo zempethu

⚙️I-bronze ye-aluminium yeyona ngxubevange yesithathu yobhedu esetyenziswa kwiigiya. Ii-alloy ze-aluminium bronze zinokumelana nokuguguleka okuphezulu kune-alloy ze-phosphor bronze kwaye zikwanokumelana nokugqwala okuphezulu. Iigiya eziqhelekileyo eziveliswa kwii-alloy ze-aluminium bronze ziquka ii-crossed helical gears (ii-helical gears) kunye nee-worm gears.

2. Ii-alloys zentsimbi

⚙️Xauyilo lwezixhoboifuna amandla angaphezulu kwezinto, ii-alloys zentsimbi zezona zilungileyo. Kwimo yayo eluhlaza, i-grey intsimbi inokuphoswa ize yenziwe ngomatshini kwiigiya.

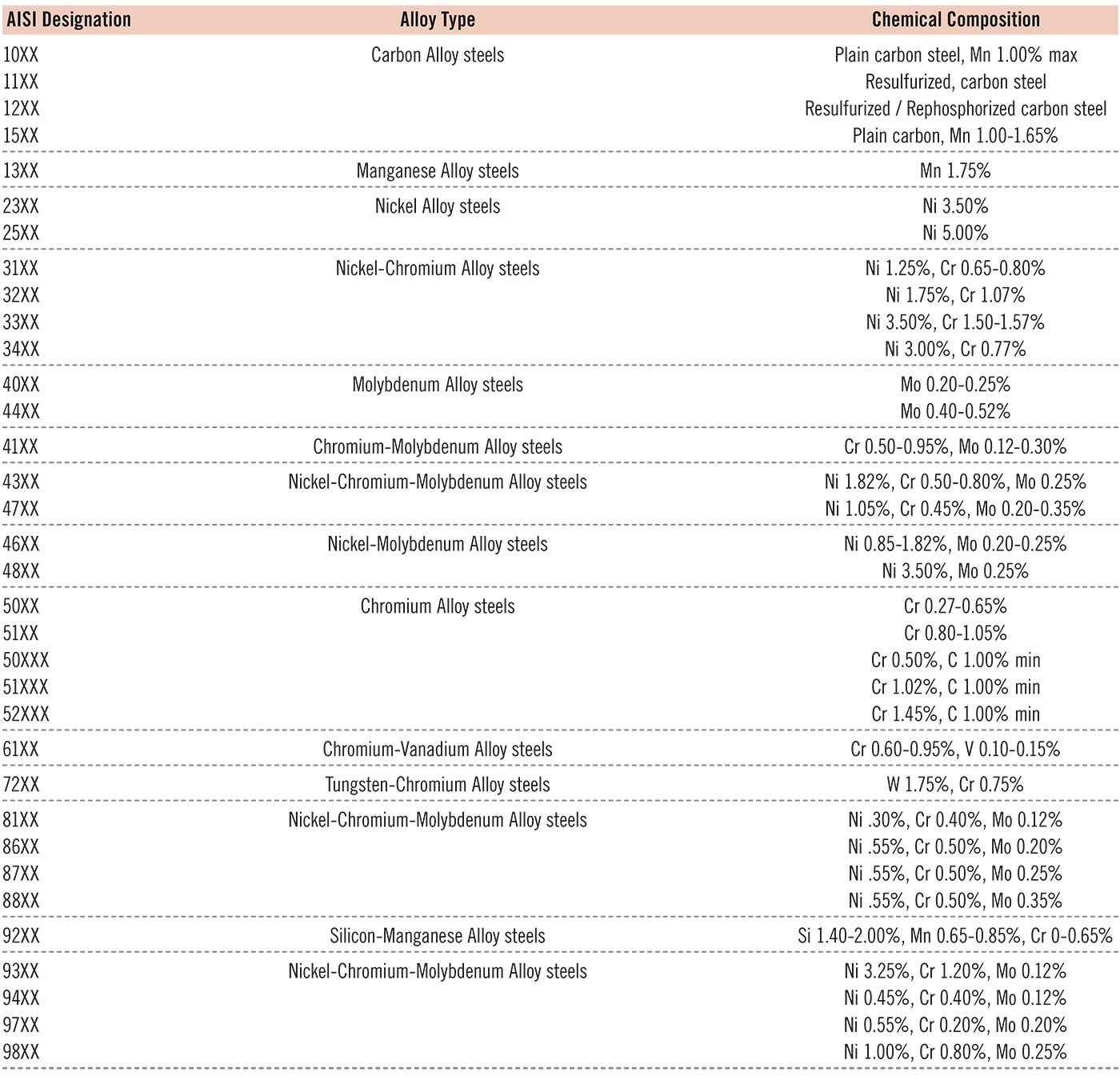

⚙️Kukho iindlela ezine eziphambili zokuchonga i-alloy yentsimbi: i-carbon steel, i-alloy steel, i-stainless steel, kunye ne-tool steel. Ii-alloy ze-carbon-steel zisetyenziselwa phantse zonke iintlobo zegiya kuba kulula ukuzisebenzisa ngomatshini, zinokuchasana kakuhle nokuguguleka, zinokuqiniswa, zifumaneka ngokubanzi, kwaye azibizi kakhulu.

⚙️Ii-alloy zentsimbi yekhabhoni zinokwahlulwahlulwa ngakumbi zibe yintsimbi ethambileyo, intsimbi yekhabhoni ephakathi, kunye nentsimbi yekhabhoni ephezulu. Ii-alloy zentsimbi ethambileyo zinomxholo wekhabhoni ongaphantsi kwe-0.30%. Ii-alloy zentsimbi yekhabhoni ephezulu zinomxholo wekhabhoni ongaphezulu kwe-0.60%, kwaye iintsimbi zentsimbi enomxholo ophakathi ziphakathi. Ezi ntsimbi zilungile kakhuluizixhobo zokushukumisa, iigiya zehelical, iirakhi zegiya,ii-bevel gears, kunye neempethu.

3. Ii-alloys ze-aluminium

⚙️Ii-alloy ze-aluminiyam ziyindlela elungileyo yokutshintsha ii-alloy zentsimbi kwizicelo ezifuna umlinganiselo ophezulu wamandla-ubunzima. Ukugqitywa komphezulu okwaziwa ngokuba yi-passivation kukhusela ii-alloy ze-aluminiyam kwi-oxidation kunye nokugqwala.

⚙️Ii-alloy ze-aluminium azinakusetyenziswa kwiindawo ezishushu kakhulu njengoko ziqala ukuguquguquka kwi-400°F. Ii-alloy ze-aluminium eziqhelekileyo ezisetyenziswa kwi-gearing yi-2024, 6061, kunye ne-7075.

⚙️Zonke ezi ntlobo zintathu ze-aluminium alloys zinganyangwa ngobushushu ukuphucula ubulukhuni bazo. Iigiya ezenziwe nge-aluminium alloys ziqukaizixhobo zokushukumisa, iigiya zehelical, iigiya ze-bevel zamazinyo ezithe tyekunye neerakhi zegiya.

4. Iithermoplastics

⚙️Iithermoplastics zezona zilungileyo kwiigiya apho ubunzima bubaluleke kakhulu. Iigiya ezenziwe ngeplastiki zinokucutshungulwa njengeegiya zesinyithi; nangona kunjalo, ezinye iithermoplastics zilungele ngakumbi ukwenziwa nge-injection molding. Enye yezona thermoplastic zixhaphakileyo yi-injection molding yi-acetal. Le nto ikwaziwa ngokuba yi-(POM). Iigiya zinokwenziwa ngayo nayiphi na i-polymer. Ezi zingenziwaizixhobo zokushukumisa, iigiya zehelical, amavili eempethu, iigiya zebhevelkunye neerakhi zegiya.

Ixesha lokuthumela: Julayi-13-2023